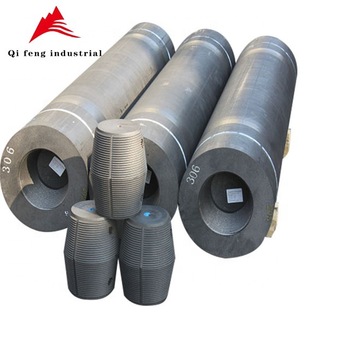

Iimpawu ze-1.EDM zezinto zegraphite.

1.1.Ukukhupha isantya somatshini.

Igraphite yinto engeyiyo isinyithi enendawo yokunyibilika ephezulu kakhulu ye-3, 650 ° C, ngelixa ubhedu lunendawo yokunyibilika ye-1, 083 ° C, ngoko ke i-electrode yegraphite inokumelana neemeko ezinkulu zokumisela ngoku.

Xa indawo yokukhuphela kunye nobungakanani bobungakanani be-electrode inkulu, iingenelo ze-high-effective machining ye-graphite material ibonakala ngakumbi.

I-conductivity ye-thermal ye-graphite yi-1/3 yobhedu, kwaye ukushisa okwenziwa ngexesha lokukhupha kungasetyenziselwa ukususa izinto zetsimbi ngokufanelekileyo. Ke ngoko, ukusebenza kakuhle kwegraphite kuphezulu kunoko kwe-electrode yobhedu kwindlela ephakathi kunye nelungileyo.

Ngokwamava okucubungula, isantya sokukhutshwa kwe-graphite electrode yi-1.5 ~ 2 amaxesha ngokukhawuleza kune-electrode yobhedu phantsi kweemeko ezichanekileyo zokusetyenziswa.

1.2.Ukusetyenziswa kwe-Electrode.

I-electrode yegraphite inomlingiswa okwaziyo ukumelana neemeko eziphakamileyo zangoku, ukongeza, phantsi kwemeko yolungiselelo olurhabaxa olufanelekileyo, kubandakanywa i-carbon steel workpieces eveliswa ngexesha lokususwa komatshini kumxholo kunye nolwelo olusebenzayo kubushushu obuphezulu bokubola kwamasuntswana ekhabhoni, isiphumo se-polarity, phantsi kwesenzo sokususwa ngokuyinxenye kumxholo, amasuntswana ekhabhoni aya kubambelela kumphezulu we-electrode ukwenza ulwaleko olukhuselayo, ulwelo olukhuselayo lwe-electrode okanye i-maleko ekhuselweyo, iqinisekisa i-electrode ekhuselweyo. inkunkuma”.

Ilahleko enkulu ye-electrode kwi-EDM ivela kwi-rough machining. Nangona izinga lelahleko liphezulu kwiimeko zokumisela ukugqiba, ilahleko iyonke iphantsi ngenxa yesibonelelo esincinci somatshini esigcinelwe iinxalenye.

Ngokubanzi, ilahleko ye-electrode yegraphite ingaphantsi kwaleyo ye-electrode yethusi kwi-rough machining yangoku enkulu kwaye kancinane ngakumbi kune-electrode yobhedu ekugqibezeleni umatshini. Ukulahleka kwe-electrode ye-graphite electrode kuyafana.

1.3.Umgangatho womphezulu.

I-particle diameter ye-graphite material ichaphazela ngokuthe ngqo ubuninzi bomhlaba we-EDM. I-diameter encinci kukuba, i-rough of surface roughness inokufumaneka.

Kwiminyaka embalwa edlulileyo usebenzisa i-particle phi 5 microns kwi-diameter ye-graphite material, eyona ndawo ingcono inokufezekisa kuphela i-VDI18 edm (i-Ra0.8 microns), namhlanje i-diameter yegrafu yezinto zegraphite ziye zakwazi ukuphumeza ngaphakathi kwe-3 microns ye-phi, indawo engcono kakhulu inokufezekisa i-VDI12 edm ezinzileyo (i-Ra0.4 mum) okanye inqanaba le-graphite ephucukileyo, kodwa i-electrode ye-graphite.

Izinto zobhedu zine-resistiveivity ephantsi kunye nesakhiwo esincinci, kwaye sinokucutshungulwa ngokuzinzileyo phantsi kweemeko ezinzima. Uburhabaxa bomphezulu bunokuba ngaphantsi kwe-Ra0.1 m, kwaye bunokucutshungulwa ngesibuko.

Ke, ukuba umatshini wokukhupha ulandela umphezulu ocolekileyo kakhulu, kufanelekile ngakumbi ukusebenzisa izinto zobhedu njenge-electrode, eyona nzuzo iphambili ye-electrode yobhedu ngaphezulu kwegraphite electrode.

Kodwa i-electrode yobhedu phantsi kwemeko yokubekwa okukhulu kwangoku, i-electrode surface ilula ukuba ibe rhabaxa, ibonakale nokuba yi-crack, kunye nezixhobo zegraphite aziyi kuba nale ngxaki, imfuneko yoburhabaxa bomphezulu ye-VDI26 (i-Ra2.0 microns) malunga nokusetyenzwa kwe-mold, usebenzisa i-electrode yegraphite inokwenziwa ukusuka kwi-coarse ukuya kwi-processing emihle, iqonda umphumo we-uniform surface, iziphene zomhlaba.

Ukongezelela, ngenxa yesakhiwo esahlukileyo segraphite kunye nobhedu, i-surface discharge point corrosion point ye-graphite electrode iqhelekile kune-electrode yethusi. Ngoko ke, xa uburhalarhume obufanayo be-VDI20 okanye ngaphezulu bucutshungulwa, i-granularity yomphezulu we-workpiece ecutshungulwayo yi-graphite electrode ihluke ngakumbi, kwaye le mpembelelo yomhlaba wenkozo ingcono kunokukhutshwa komphezulu we-electrode yobhedu.

1.4.Ukuchaneka komatshini.

I-coefficient yokwandiswa kwe-thermal yezinto ze-graphite zincinci, i-coefficient yokwandiswa kwe-thermal yezinto zobhedu ngamaxesha angama-4 kwizinto ze-graphite, ngoko ke ekuqhutyweni kokukhutshwa, i-electrode ye-graphite ayinakukwazi ukuguqulwa kune-electrode yobhedu, enokufumana ukuchaneka okuzinzile nokuthembekileyo.

Ngokukodwa xa ubambo olunzulu nolumxinwa lucutshungulwa, ubushushu obuphezulu bendawo benza ukuba i-electrode yobhedu igobe ngokulula, kodwa i-electrode yegraphite ayifuni.

Kwi-electrode yobhedu ene-deep-diameter ratio, ixabiso elithile lokwandiswa kwe-thermal kufuneka lihlawulwe ukuze lilungise ubungakanani ngexesha lokucwangciswa kwe-machining, ngelixa i-graphite electrode ayifuni.

1.5.Ubunzima be-Electrode.

Izinto zegraphite zincinci kunobhedu, kwaye ubunzima be-electrode yegraphite yomthamo ofanayo yi-1/5 kuphela ye-electrode yobhedu.

Ingabonwa ukuba ukusetyenziswa kwegraphite kufanelekile kakhulu kwi-electrode enomthamo omkhulu, onciphisa kakhulu umthwalo we-spindle yesixhobo somatshini we-EDM. I-electrode ayiyi kubangela ukuphazamiseka kwi-clamping ngenxa yobunzima bayo obukhulu, kwaye iya kuvelisa ukuchithwa kwe-deflection kwi-processing, njl.

1.6.Ubunzima bokuvelisa i-Electrode.

Ukusebenza komatshini wezinto zegraphite kulungile. Ukumelana nokusika kuphela i-1/4 yobhedu. Ngaphantsi kweemeko ezichanekileyo zokucubungula, ukusebenza kakuhle kwe-electrode yokugaya i-graphite yi-2 ~ 3 amaxesha e-electrode yobhedu.

I-electrode yegraphite kulula ukuyisusa i-Angle, kwaye ingasetyenziselwa ukucubungula i-workpiece ekufuneka igqitywe ngama-electrode amaninzi kwi-electrode enye.

Isakhiwo esiyingqayizivele se-particle ye-graphite material ivimbela ukuba i-burrs ingenzeki emva kokugaya i-electrode kunye nokwenza, enokuthi ihlangabezane ngokuthe ngqo neemfuno zokusetyenziswa xa i-burrs ingasuswa kalula kwi-modeling eyinkimbinkimbi, ngaloo ndlela isusa inkqubo yokupolisha ngesandla kwe-electrode kunye nokuphepha ukuguqulwa kwemilo kunye nephutha lobungakanani obubangelwa ukupolisha.

Kufuneka kuqatshelwe ukuba, ngenxa yokuba igraphite iqokelela uthuli, i-graphite yokugaya iya kuvelisa uthuli oluninzi, ngoko umatshini wokugaya kufuneka ube nesitywina kunye nesixhobo sokuqokelela uthuli.

Ukuba kuyimfuneko ukusebenzisa i-edM ukucubungula i-electrode yegraphite, ukusebenza kwayo akuhambelani njengezinto zobhedu, isantya sokusika simalunga nama-40% kancinci kunobhedu.

1.7.Ukufakwa kunye nokusetyenziswa kwe-Electrode.

Izinto zegraphite zinepropathi elungileyo yokudibanisa. Ingasetyenziselwa ukudibanisa i-graphite kunye ne-fixture ngokugaya i-electrode kunye nokukhupha, oko kunokugcina inkqubo ye-machining screw hole kwizinto ze-electrode kunye nokugcina ixesha lokusebenza.

Izinto zegraphite zincinci, ngakumbi i-electrode encinci, emxinwa kwaye ende, ekulula ukuyiqhekeza xa iphantsi kwamandla angaphandle ngexesha lokusetyenziswa, kodwa inokwazi ngokukhawuleza ukuba i-electrode yonakalisiwe.

Ukuba i-electrode yobhedu, iya kugoba kuphela kwaye ingaphuli, eyingozi kakhulu kwaye inzima ukuyifumana kwinkqubo yokusetyenziswa, kwaye iya kukhokelela ngokulula kwi-scrap ye-workpiece.

1.8.Ixabiso.

Izinto zobhedu zisisixhobo esingahlaziywanga, ixabiso lexabiso liya kuba libiza kakhulu kwaye libiza kakhulu, ngelixa ixabiso lezinto zegraphite lithanda ukuzinza.

Ixabiso lezinto zobhedu liyenyuka kwiminyaka yakutshanje, abenzi abakhulu begraphite ekuphuculeni inkqubo yokuveliswa kwegraphite benza inzuzo yabo yokukhuphisana, ngoku, phantsi komthamo ofanayo, ukuqheleka kwexabiso lezinto ezibonakalayo zegraphite electrode kunye nexabiso lezinto zobhedu ze-electrode, kodwa igraphite inokufezekisa ukusetyenzwa okusebenzayo, kunokusebenzisa i-electrode yobhedu ukugcina inani elikhulu leeyure zokusebenza, ezilingana ngokuthe ngqo nexabiso lemveliso.

Ukudibanisa, phakathi kweempawu ze-8 ze-edM ze-graphite electrode, iingenelo zayo zicacile: ukusebenza kakuhle kwe-electrode yokugaya kunye nokukhutshwa kwe-discharge kubhetele kakhulu kune-electrode yobhedu; I-electrode enkulu inobunzima obuncinci, uzinzo olufanelekileyo lwe-dimensional, i-electrode ebhityileyo ayilula ukuyikhubaza, kwaye ukuthungwa komphezulu kungcono kune-electrode yobhedu.

Ukungalungi kwezinto zegraphite kukuba ayifanelekanga ukulungiswa kokukhutshwa kwamanzi phantsi kwe-VDI12 (Ra0.4 m), kunye nokusebenza kakuhle kokusebenzisa i-edM ukwenza i-electrode iphantsi.

Nangona kunjalo, ngokwembono ebonakalayo, esinye sezizathu ezibalulekileyo ezichaphazela ukukhuthazwa okusebenzayo kwezixhobo zegraphite eChina kukuba umatshini okhethekileyo wokulungisa igraphite uyafuneka kwi-electrode yokugaya, ebeka phambili iimfuno ezintsha zokulungiswa kwezixhobo zamashishini okubumba, amanye amashishini amancinci angabinayo le meko.

Ngokubanzi, izibonelelo zee-electrode zegraphite zigubungela uninzi lwezihlandlo zokusetyenzwa kwe-edM, kwaye zifanelekile ukuthandwa nokusetyenziswa, kunye neenzuzo zexesha elide. Ukunqongophala kokulungiswa kwendawo efanelekileyo kunokwenziwa ngokusetyenziswa kwee-electrode zethusi.

2.Ukukhethwa kwezinto ze-graphite electrode ze-EDM

Kwimathiriyeli yegraphite, kukho ikakhulu ezi zalathisi zine zilandelayo ezimisela ngokuthe ngqo ukusebenza kwezinto:

1) I-avareji ye-particle ye-diameter yezinto

Umyinge we-particle ububanzi bezinto eziphathekayo zichaphazela ngokuthe ngqo imeko yokukhutshwa kwezinto.

Incinci i-particle ye-avareji ye-graphite material, i-uniform ifanayo yokukhutshwa, ukuzinza ngakumbi imeko yokukhupha, ingcono umgangatho womphezulu, kwaye ilahleko encinci.

Inkulu i-avareji yesayizi ye-particle kukuba, izinga lokususa elingcono linokufumaneka kwi-machining rough, kodwa umphumo wokugqiba umbi kwaye ilahleko ye-electrode inkulu.

2) Amandla okugoba kwezinto

Amandla aguquguqukayo ezinto eziphathekayo abonisa ngokuthe ngqo amandla ayo, ebonisa ukuqina kwesakhiwo sayo sangaphakathi.

Isixhobo esinamandla aphezulu sinokumelana nokusebenza kakuhle. Kwi-electrode echanekileyo ephezulu, izinto eziphathekayo ezinamandla zifanele zikhethwe ngokusemandleni.

3) Ukuqina konxweme lwento

I-graphite inzima kunezixhobo zetsimbi, kwaye ukulahlekelwa kwesixhobo sokusika kukhulu kunokwentsimbi yokusika.

Ngelo xesha, ubunzima obuphezulu bezinto zegraphite ekulawuleni ilahleko yokukhupha kungcono.

4) Ukuxhathisa okungokwemvelo kwezinto

Umyinge wokukhutshwa kwezinto zegraphite ezinokumelana okuphezulu kwendalo kuya kucotha kunoko kunokumelana okuphantsi.

Ukuphakama kwe-resistivity yendalo, encinci ilahleko ye-electrode, kodwa iphezulu i-resistivity yendalo, ukuzinza kokukhutshwa kuya kuchaphazeleka.

Okwangoku, kukho amanqanaba amaninzi ahlukeneyo egraphite afumanekayo kubathengisi abaphambili behlabathi begraphite.

Ngokuqhelekileyo ngokomlinganiselo we-particle ububanzi bezinto ze-graphite eziza kuhlukaniswa, i-particle diameter ≤ 4 m ichazwa njenge-graphite ecocekileyo, iinqununu kwi-5 ~ 10 m zichazwa njenge-graphite ephakathi, iinqununu kwi-10 m ngaphezulu zichazwa njengegraphite enqabileyo.

Incinci i-particle diameter, into ebiza kakhulu, i-graphite efanelekileyo inokuthi ikhethwe ngokweemfuno kunye neendleko ze-EDM.

3.Ukwenziwa kwe-electrode yegraphite

I-electrode yegraphite yenziwa ikakhulu ngokusila.

Ukusuka kwindawo yokujonga iteknoloji yokucubungula, igraphite kunye nobhedu zizinto ezimbini ezahlukeneyo, kwaye iimpawu zabo zokusika ezihlukeneyo kufuneka ziphathwe kakuhle.

Ukuba i-electrode yegraphite icutshungulwa yinkqubo ye-electrode yethusi, iingxaki ziya kwenzeka ngokuqinisekileyo, njengokuphuka rhoqo kwephepha, elifuna ukusetyenziswa kwezixhobo ezifanelekileyo zokusika kunye neeparitha zokusika.

Ukutshiza i-electrode yegraphite kunobhedu besixhobo se-electrode ukunxiba, kuqwalaselo lwezoqoqosho, ukhetho lwesixhobo se-carbide sesona sinoqoqosho, khetha isixhobo sokugquma idayimane (esibizwa ngokuba yi-graphite imela) ixabiso libiza kakhulu, kodwa isixhobo sedayimane sokwaleka ubomi obude benkonzo, ukuchaneka okuphezulu kokusebenza, inzuzo yezoqoqosho iyonke ilungile.

Ubungakanani be-Angle yangaphambili yesixhobo nayo ichaphazela ubomi bayo benkonzo, i-0 ° yangaphambili ye-Angle yesixhobo iya kuba yi-50% ephezulu kune-15 ° yangaphambili ye-Angle yobomi benkonzo yesixhobo, ukuzinza kokusika kungcono, kodwa i-Angle enkulu, i-machining surface, ukusetyenziswa kwe-15 ° ye-Angle yesixhobo kunokufikelela eyona nto ingcono.

Isantya sokusika kwi-machining sinokuhlengahlengiswa ngokwemilo ye-electrode, ngokuqhelekileyo i-10m / min, efana ne-machining ye-aluminium okanye iplastiki, isixhobo sokusika sinokuthi sithe ngqo kwaye siphume kwi-workpiece kwi-machining rough, kwaye i-phenomenon ye-Angle yokuwa kunye nokuqhekeka kulula ukwenzeka ekugqibeni umatshini, kwaye indlela yokuhamba ngokukhawuleza ithatha imela.

I-electrode yegraphite kwinkqubo yokusika iya kuvelisa uthuli oluninzi, ukwenzela ukuba kuthintelwe amasuntswana egraphite arhole i-spindle yomatshini kunye ne-screw, kukho izisombululo ezibini eziphambili ngoku, enye kukusebenzisa umatshini okhethekileyo wokulungisa igraphite, enye yindawo eqhelekileyo yokulungisa iziko, exhotyiswe ngesixhobo esikhethekileyo sokuqokelela uthuli.

Umatshini okhethekileyo wegraphite wokusila ngesantya esiphezulu kwimarike unomsebenzi ophakamileyo wokusila kwaye unokugqiba ngokulula ukwenziwa kwee-electrode ezintsonkothileyo ngokuchaneka okuphezulu kunye nomgangatho olungileyo womphezulu.

Ukuba i-EDM iyadingeka ukwenza i-electrode ye-graphite, kucetyiswa ukuba kusetyenziswe i-graphite ecocekileyo kunye ne-particle encinci.

Ukusebenza komatshini wegraphite kubi, incinci i-particle diameter, iphezulu ukusika ukusebenza kakuhle kunokufumaneka, kwaye iingxaki ezingaqhelekanga ezifana nokuphulwa rhoqo kweentambo kunye nomphetho womphezulu unokuphetshwa.

Iiparamitha ze-4.EDM ze-graphite electrode

Ukukhethwa kweeparamitha ze-EDM zegraphite kunye nobhedu zihluke kakhulu.

Iiparamitha ze-EDM ikakhulu zibandakanya okwangoku, ububanzi be-pulse, i-pulse gap kunye ne-polarity.

Oku kulandelayo kuchaza isiseko sokusetyenziswa okunengqiqo kwezi parameters ezinkulu.

Ukuxinana kwangoku kwe-electrode yegraphite ngokuqhelekileyo yi-10 ~ 12 A/cm2, inkulu kakhulu kune-electrode yobhedu. Ngoko ke, phakathi koluhlu lwangoku oluvunyelweyo kwindawo ehambelanayo, inkulu ikhoyo ngoku ikhethiweyo, ngokukhawuleza isantya sokukhutshwa kwegraphite siya kuba, ilahleko encinci ye-electrode iya kuba, kodwa uburhabaxa bomhlaba buya kuba bukhulu.

Ubukhulu be-pulse ububanzi, ilahleko ye-electrode ephantsi iya kuba.

Nangona kunjalo, ububanzi be-pulse enkulu buya kwenza uzinzo lokucubungula lube mandundu, kwaye isantya sokucubungula sicotha kwaye umphezulu womhlaba urhabaxa.

Ukuze kuqinisekiswe ilahleko ye-electrode ephantsi ngexesha lomatshini orhabaxa, ubukhulu be-pulse ububanzi budla ngokusetyenziswa, obunokuqonda ngokufanelekileyo ilahleko ephantsi yokwenziwa kwe-electrode yegraphite xa ixabiso liphakathi kwe-100 kunye ne-300 yase-US.

Ukuze ufumane umgangatho ococekileyo kunye nesiphumo esizinzileyo sokukhupha, kufuneka kukhethwe ububanzi obuncinci be-pulse.

Ngokubanzi, ububanzi bokubetha kwe-electrode yegraphite bumalunga nama-40% ngaphantsi kobo be-electrode yobhedu.

Umsantsa we-pulse ikakhulu uchaphazela isantya somatshini wokukhupha kunye nokuzinza komatshini. Ixabiso elikhulu, ngcono uzinzo lomatshini luya kuba, oluluncedo ekufumaneni ukufana komphezulu ongcono, kodwa isantya somatshini siya kuncitshiswa.

Ngaphantsi kwemeko yokuqinisekisa ukuzinza kokusebenza, ukusebenza okuphezulu kokusebenza kunokufumaneka ngokukhetha i-gap encinci ye-pulse, kodwa xa imeko yokukhutshwa ingazinzile, ukusebenza okuphezulu kokusebenza kunokufumaneka ngokukhetha i-gap enkulu ye-pulse.

Kwi-graphite electrode discharge machining, i-gap ye-pulse kunye nobubanzi be-pulse ngokuqhelekileyo ibekwe kwi-1: 1, ngelixa i-electrode machining yobhedu, i-pulse gap kunye nobubanzi be-pulse buhlala bubekwe kwi-1: 3.

Phantsi kokusetyenzwa kwegraphite okuzinzileyo, umlinganiselo ohambelanayo phakathi kwe-pulse gap kunye nobubanzi be-pulse ungahlengahlengiswa ube yi-2:3.

Kwimeko yokukhutshwa kwe-pulse encinci, kunenzuzo ukwenza umgca wokugubungela kwindawo ye-electrode, eluncedo ekunciphiseni ukulahleka kwe-electrode.

Ukukhethwa kwe-polarity ye-graphite electrode kwi-EDM ngokusisiseko kufana ne-electrode yobhedu.

Ngokutsho kwempembelelo ye-polarity ye-EDM, i-polarity machining echanekileyo idla ngokusetyenziswa xa kusenziwa i-machining die steel, oko kukuthi, i-electrode idibaniswe kwipali echanekileyo yonikezelo lwamandla, kwaye i-workpiece ixhunywe kwi-pole negative yokunikezelwa kwamandla.

Ukusebenzisa ubukhulu bangoku kunye nobubanzi be-pulse, ukukhetha i-polarity machining inokufikelela kwilahleko ephantsi kakhulu ye-electrode. Ukuba i-polarity ayilunganga, ukulahleka kwe-electrode kuya kuba kukhulu kakhulu.

Kuphela xa ubuso bufuneka ukuba bucutshungulwe kakuhle ngaphantsi kwe-VDI18 (i-Ra0.8 m) kunye nobubanzi be-pulse buncinci kakhulu, ukucutshungulwa kwe-polarity embi kusetyenziselwa ukufumana umgangatho ongcono, kodwa ukulahleka kwe-electrode kukhulu.

Ngoku izixhobo zomatshini we-CNC edM zixhotyiswe ngeeparamitha ze-graphite discharge machining.

Ukusetyenziswa kweeparamitha zombane zihlakaniphile kwaye ziyakwazi ukuveliswa ngokuzenzekelayo yinkqubo yengcali yesixhobo somatshini.

Ngokuqhelekileyo, umatshini unokuqwalasela iiparitha zokucubungula eziphuculweyo ngokukhetha isibini sezinto eziphathekayo, uhlobo lwesicelo, ixabiso le-roughness ye-surface kunye nokufaka indawo yokucubungula, ubunzulu bokucubungula, ukulinganisa ubungakanani be-electrode, njl. Ngexesha leprogram.

Isetelwe i-graphite electrode ye-edm yesixhobo somatshini wethala leencwadi iparameters ezityebileyo, uhlobo lwemathiriyeli lunokukhetha kwigraphite erhabaxa, igraphite, igraphite ihambelana nezixhobo ezahlukeneyo zokusebenza, ukwahlulahlula uhlobo lwesicelo somgangatho, igroove enzulu, indawo ebukhali, indawo enkulu, umngxuma omkhulu, onje ngokucokisekileyo, ikwabonelela ngelahleko ephantsi, umgangatho, ukusebenza kakuhle okuphezulu kunye nokunye okuninzi okukhethiweyo okukhethiweyo.

5.Isiphelo

Izinto ezintsha ze-graphite electrode zifanelekile ukuthandwa ngamandla kwaye izibonelelo zayo ziya kuqatshelwa ngokuthe ngcembe kwaye zamkelwe kushishino lokwenziwa ngundo lwasekhaya.

Ukhetho oluchanekileyo lwemathiriyeli yegraphite electrode kunye nophuculo lwamakhonkco etekhnoloji anxulumeneyo kuya kuzisa ukusebenza kakuhle okuphezulu, umgangatho ophezulu kunye nenzuzo yexabiso eliphantsi kumashishini okuvelisa ukubumba.

Ixesha lokuposa: Dec-04-2020