Iielectrode zegraphite zamandla aphezulu kakhulu, ngokutshintsha iielectrode zobhedu kunye neeelectrode zegraphite zokwenziwa kokungunda, mfutshane kakhulu umjikelo wokwenziwa kokungunda, ukwandisa imveliso yabasebenzi, kunye nokunciphisa iindleko zokwenziwa kokungunda. Kwiminyaka yakutshanje, ngokungeniswa kokungunda okuchanekileyo kunye nokungunda okusebenzayo okuphezulu (kunye nemijikelo yokungunda emifutshane), iimfuno zabantu zokuvelisa ukungunda ziye zanyuka ngokunyuka. Ngenxa yemida eyahlukeneyo yee-electrode zethusi ngokwazo, iye yasilela kakhulu ukuhlangabezana neemfuno zophuhliso lweshishini lokubumba. I-graphite, njengento ye-EDM ye-electrode, isetyenziswe ngokubanzi kwi-mold industry ngenxa yeenzuzo zayo ezifana ne-machinability ephezulu, ubunzima obulula, ukubunjwa ngokukhawuleza, izinga eliphantsi kakhulu lokwandiswa, ilahleko ephantsi kunye nokugqoka lula. Akunakuphepheka ukuba iya kuthatha indawo ye-electrode yobhedu.

1. Iimpawu zeGraphite Electrode Materials

CNC machining features fast processing speed, high machinability kunye nokunxiba lula. Isantya sokusebenza koomatshini begraphite si-3 ukuya ku-5 kumaxesha ee-electrode zobhedu, kwaye isantya sokucubungula ngokuchanekileyo sibalaseleyo. Ngaphezu koko, amandla ayo aphezulu kakhulu. Kwi-ultra-high (50 ukuya kwi-90mm) kunye ne-ultra-thin (0.2 ukuya kwi-0.5mm) i-electrodes, ayinakukwazi ukuguqulwa ngexesha lokucubungula. Ngaphezu koko, kwiimeko ezininzi, iimveliso kufuneka zibe nefuthe elihle kakhulu lokuthungwa. Oku kufuna ukuba xa kusenziwa ii-electrode, kufuneka zenziwe njengee-electrodes eziziinkunzi kangangoko kunokwenzeka. Nangona kunjalo, kukho iindlela ezahlukeneyo zokucocwa kweekona ezifihliweyo ngexesha lokuveliswa kwee-electrode zamadoda. Ngenxa yepropathi elula yokulungisa i-graphite, le ngxaki ingasombululwa ngokulula kwaye inani lee-electrode lingancitshiswa kakhulu, apho i-electrodes yethusi ayinakufezekisa.

2. Ukuqulunqwa kwe-EDM ngokukhawuleza, ukwandiswa kwe-thermal encinci kunye nokulahleka okuphantsi: Ngenxa ye-conductivity yombane engcono yegraphite kunobhedu, ukukhutshwa kwayo ngokukhawuleza kunobhedu, ibe yi-3 ukuya ku-5 ngamaxesha obhedu. Ngaphezu koko, inokumelana nomsinga omkhulu kakhulu ngexesha lokukhupha, nto leyo iluncedo ngakumbi kumatshini wokukhupha umbane. Okwangoku, phantsi komthamo ofanayo, ubunzima begraphite ngama-1/5 amaxesha obhedu, okunciphisa kakhulu umthwalo we-EDM. Ineenzuzo ezinkulu ekuveliseni ii-electrode ezinkulu kunye nee-electrodes zamadoda. Ubushushu be-sublimation yegraphite yi-4200℃, eyi-3 ukuya ku-4 ngokuphindwe kabini kunobhedu (ubushushu be-sublimation yobhedu yi-1100℃). Kwiqondo lokushisa eliphezulu, utshintsho

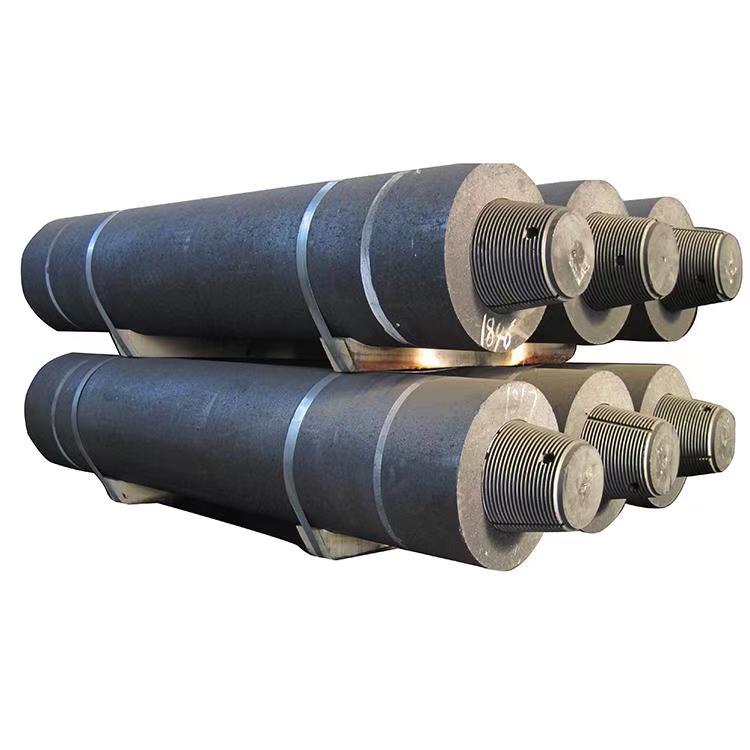

Ultra-high amandla graphite electrode

Incinci kakhulu ngokwemilo (1/3 ukuya kwi-1/5 yobhedu phantsi kweemeko zombane ezifanayo) kwaye ayithambi. Amandla okukhutshwa angakwazi ukudluliselwa kwi-workpiece ngokufanelekileyo kunye nokusetyenziswa okuphantsi. Ngenxa yokuba amandla egraphite okunene ayanda kumaqondo obushushu aphezulu, anokunciphisa ngempumelelo ilahleko yokukhupha (ilahleko yegraphite yi-1/4 yobhedu), iqinisekisa umgangatho wokulungisa.

3. Ubunzima bokukhanya kunye neendleko eziphantsi: Kwiindleko zokuvelisa isethi yokubumba, ixesha le-CNC machining, ixesha le-EDM, kunye nokugqoka i-electrode ye-electrode i-akhawunti yobuninzi beendleko ezipheleleyo, kwaye zonke ezi zinqunywe yi-electrode material ngokwayo. Xa kuthelekiswa nobhedu, isantya somatshini kunye nesantya se-EDM segraphite zombini zi-3 ukuya kuma-5 amaxesha obhedu. Ngeli xesha, imbonakalo yokunxiba okuncinci kunye nokuveliswa kwe-electrode edibeneyo yegraphite inokunciphisa inani lee-electrode, ngaloo ndlela kuncitshiswe ukusetyenziswa kwezinto kunye nexesha lomatshini lee-electrode. Zonke ezi zinto zinokunciphisa kakhulu iindleko zemveliso yokubumba

2. Iimfuno kunye neeMpawu zokuLungiswa koMatshini kunye noMbane weGraphite Electrodes

1. Ukuveliswa kwee-electrode: Ukuveliswa kwee-electrode zobuchwephesha begraphite ubukhulu becala kusetyenziswa izixhobo zomatshini wesantya esiphezulu sokusetyenzwa. Izixhobo zomatshini kufuneka zibe nokuzinza okulungileyo, kunye nokunyakaza okufanayo kunye nokuzinzileyo kwe-axis ezintathu ngaphandle kokunyakaza. Ngaphezu koko, ukuchaneka okujikelezayo kwamacandelo afana ne-shaft ephambili kufuneka kwakhona kube kuhle kangangoko kunokwenzeka. I-electrode inokucutshungulwa kwizixhobo zomatshini jikelele, kodwa inkqubo yokubhala indlela yesixhobo ihluke kuleyo ye-electrode yobhedu.

I-2.EDM yokukhupha umbane we-machining graphite electrode yi-carbon electrode. Ngenxa yokuba i-graphite ine-conductivity efanelekileyo yombane, inokonga ixesha elininzi kwi-machining yokukhupha umbane, enye yezizathu zokuba i-graphite isetyenziswe njenge-electrode.

3. IiMpawu zokuLungisa ii-Electrodes zeGraphite: Igraphite ye-Industrial graphite ilukhuni kwaye i-brittle, ibangela ukuguga okuqatha kwizixhobo ngexesha lomatshini we-CNC. Ngokuqhelekileyo, kucetyiswa ukusebenzisa izixhobo ezifakwe nge-alloy eqinile okanye idayimane. Xa rough machining graphite, isixhobo inokubekwa ngqo kwaye off workpiece. Nangona kunjalo, ngexesha lokugqitywa komatshini, ukuthintela ukuqhekeka kunye nokuqhekeka, isixhobo esilula kunye nendlela yokunqumla ngokukhawuleza ihlala yamkelwa.

Ngokuqhelekileyo, igraphite ayifane iphuke xa ubunzulu bokusika bungaphantsi kwe-0.2mm, kwaye umgangatho ongcono wodonga olusecaleni unokufumaneka. Uthuli oluveliswe ngexesha CNC machining of electrode graphite mkhulu ngokwentelekiso kwaye angahlasela iileyili isikhokelo, izikrufu zokukhokela kunye nokusonta isixhobo umatshini, njl. Oku kufuna ukuba isixhobo umatshini wokulungisa igraphite inezixhobo ezihambelanayo zokujongana nothuli lwegraphite, kunye nokusebenza kokutywinwa komatshini womatshini kufuneka kwakhona kube kuhle kuba igraphite inetyhefu. I-graphite powder yinto enovelwano kakhulu kwiikhemikhali. I-resistivity yayo iyatshintsha kwiindawo ezahlukeneyo, oku kuthetha ukuba ixabiso layo lokumelana liyahluka. Nangona kunjalo, kukho into enye ehlala ingaguquki: i-graphite powder yenye yezinto ezigqwesileyo ezingenayo i-metallic conductive. Ngethuba nje i-graphite powder igcinwe kwi-insulating into ngaphandle kokuphazamiseka, njengomsonto omncinci, iya kuhlala ifakwe umbane. Kodwa yintoni ixabiso lokumelana? Akukho mfanekiso ocacileyo wale xabiso nokuba, kuba ukulunga kwe-graphite powder kuyahluka, kwaye ixabiso lokumelana ne-graphite powder elisetyenziswe kwizinto ezahlukeneyo kunye neendawo ezingqongileyo ziya kuba zihluke.

Usenokungazi ukuba umgubo wegraphite ococekileyo nawo unosetyenziso oluqhubayo:

Ngokuqhelekileyo, irabha iyagquma. Ukuba i-conductivity yombane iyadingeka, izinto eziqhubayo kufuneka zongezwe. I-graphite powder ine-conductivity egqwesileyo yombane kunye neempawu zokudiliza zokuthambisa. Igraphite icutshungulwa ibe ngumgubo wegraphite, eneempawu ezibalaseleyo zokuthambisa kunye nokuqhuba. Ukuphakama kokucoceka kwe-graphite powder, ngcono ukusebenza kwayo komqhubi. Iifektri ezininzi zeemveliso zerabha ezikhethekileyo zidinga irabha eqhubayo. Emva koko, ngaba umgubo wegraphite unokongezwa kwirabha ukuze kuqhutywe umbane? Impendulo ngu-ewe, kodwa kukho umbuzo: Yintoni umlinganiselo we-graphite powder kwi-rubber? Amanye amashishini asebenzisa umlinganiselo ongekho ngaphezulu kwe-30%, osetyenziswa kwimveliso yerabha engagugiyo njengamatayara emoto, njl. Iimveliso ezinjalo kuphela zinokuqhuba umbane. Umgaqo osisiseko we-conductivity kukuba umqhubi akakwazi ukuphazamiseka, njengocingo. Ukuba iphazamisekile embindini, ayiyi kufakelwa umbane. I-powder conductive graphite powder kwi-rubber conductive yi-conductor Ukuba i-graphite powder ivalwe yi-rubber ye-insulating, ayiyi kuphinda iqhube umbane. Ngoko ke, ukuba umlinganiselo we-graphite powder uphantsi kakhulu, umphumo wokuqhuba unokuthi ungabikho.

I-graphite powder yinto enovelwano kakhulu kwiikhemikhali. I-resistivity yayo iyatshintsha kwiindawo ezahlukeneyo, oku kuthetha ukuba ixabiso layo lokumelana liyahluka. Nangona kunjalo, kukho into enye ehlala ihleli: i-high-purity graphite powder yenye yezinto ezigqwesileyo ezingenayo i-metallic conductive. Ngethuba nje i-graphite powder igcinwe kwi-insulating into ngaphandle kokuphazamiseka, njengomsonto omncinci, iya kuhlala ifakwe umbane. Kodwa yintoni ixabiso lokumelana? Akukho mfanekiso ocacileyo wale xabiso nokuba, kuba ukulunga kwe-graphite powder kuyahluka, kwaye ixabiso lokumelana ne-graphite powder elisetyenziswe kwizinto ezahlukeneyo kunye neendawo ezingqongileyo ziya kuba zihluke.

Ixesha lokuposa: May-09-2025