Kwiminyaka yakutshanje, ngokusetyenziswa kakhulu kokungunda kwegraphite, ixabiso lonyaka lokungunda kwishishini lomatshini liphindwe ka-5 lexabiso lilonke lazo zonke iintlobo zezixhobo zoomatshini, kwaye ilahleko enkulu yobushushu ichasene kakhulu nemigaqo-nkqubo ekhoyo yokonga amandla eTshayina.

Ngokophononongo, ngenxa yezixhobo zomngundo kunye namaxabiso amandla enyuka kabukhali kunye nezinye izizathu, inzuzo yemveliso yemveliso yokungunda yawa kunyaka ophelileyo; Ukuze uphile kwaye uphuhlise, amashishini amaninzi amkela.

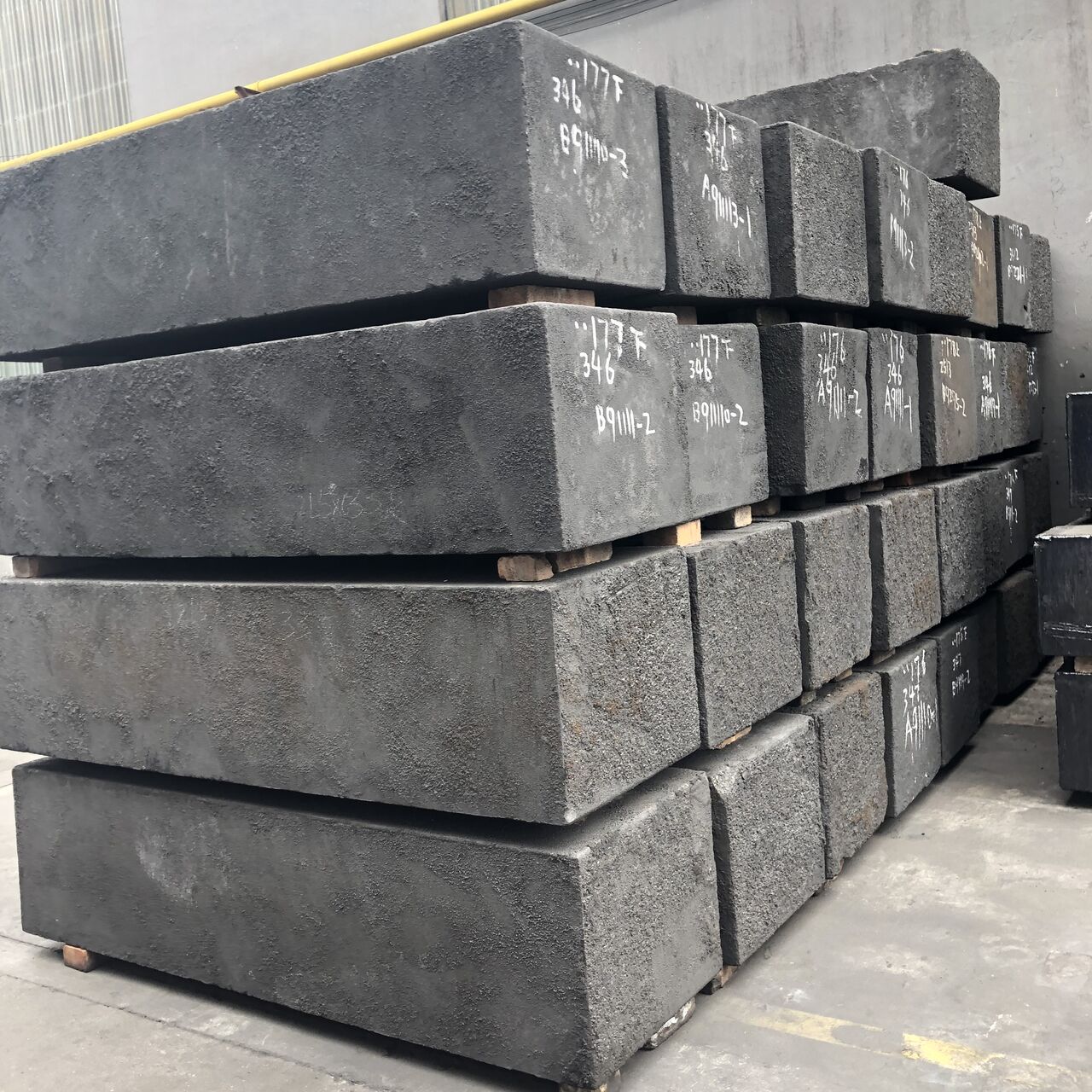

Ukutshintsha kwezinto kusetyenziswa njengomlinganiselo omkhulu wenguqu kunye nophuhliso.Kuyaqondwa ukuba iinkampani ezininzi zisungule izixhobo zokukhupha i-graphite spark, kwimveliso yokubumba idlala indima ebaluleke kakhulu.Xa kuthelekiswa nomngundo wobhedu wendabuko, izinto zegraphite zineenzuzo zokuchaneka okuphezulu kunye nesiphumo esihle somphezulu, ngakumbi kwiprosesa yokubumba yokuchaneka, eyinkimbinkimbi, enodonga oluncinci olunodonga olunzima, i-compat material inenzuzo enkulu, i-copper, i-advanteji enzima. Ukusetyenziswa okuncinci, isantya sokukhupha ngokukhawuleza, ubunzima obuncinci kunye ne-coefficient yokwandiswa kwe-thermal encinci, ngoko ke i-electrode yobhedu iye ngokuthe ngcembe ibe yeyona nto iphambili kwizinto zokucoca ukukhutshwa.

1. Isantya esikhawulezayo; Ukukhutshwa kwegraphite kumaxesha angama-2-3 ngokukhawuleza kunobhedu, kwaye izinto eziphathekayo akulula ukuzikhubaza. Ineenzuzo ezicacileyo ekusetyenzweni kwe-electrode eyomeleziweyo encinci. Indawo yokuthambisa yobhedu ijikeleze i-1000 degrees, kwaye kulula ukuyikhubaza ngenxa yobushushu.

2. Ubunzima obulula;Ubuninzi begraphite yi-1/5 kuphela yobhedu. Xa i-electrode enkulu icutshungulwa ngokukhutshwa, umthwalo wesixhobo somatshini (EDM) unokuncitshiswa ngokufanelekileyo, ofaneleke ngakumbi ukusetyenziswa kwesikhunta esikhulu.

3. Inkcitho encinci; Njengoko i-oyile yentlantsi ine-athom ze-C, ubushushu obuphezulu bubangela ukuba iiathom ze-C ezikwi-spark oil zibole xa kusenziwa ulwelo, kwaye kwenziwa ifilimu ekhuselayo kumphezulu we-graphite electrode, ehlawulela ukulahleka kwe-electrode yegraphite.

4. Akukho burrs;Emva kokuba i-electrode yobhedu isetyenzisiwe, ii-burrs kufuneka zisuswe ngesandla. Nangona kunjalo, akukho burrs emva kokuba i-graphite icutshungulwe, engagcini nje kuphela iindleko ezininzi kunye nabasebenzi, kodwa yenza kube lula ukuqonda imveliso ezenzekelayo.

5. Ukupholisha okulula;Kuba ukuxhathisa ukusika kwegraphite yi-1/5 kuphela yobhedu, kulula ukuguba kunye nokupolisha ngesandla.

Vi. Ixabiso eliphantsi;Ngenxa yokunyuka kwexabiso lobhedu kwiminyaka yakutshanje, ixabiso legraphite kuzo zonke iinkalo lingaphantsi kwelo lobhedu.Ngaphantsi komthamo ofanayo wendalo yonke yekhabhoni yaseMpuma, ixabiso leemveliso zegraphite ngama-30% ukuya kuma-60% ngaphantsi kunelo lobhedu, ixabiso lizinzile, kwaye ukusetyenzwa kwexesha elifutshane ngokuhambelana nokuguquguquka kwexabiso lokusingqongileyo kukuguquguquka okuncinci kokusingqongileyo. imboni yokuvelisa, izinto ze-graphite electrode ziza kutshintsha ngokuthe ngcembe i-electrode yobhedu kwaye idlale indima ebalulekileyo kwi-EDM.Ngokufanayo, ekukhuphisaneni okunyukayo kwimarike yokubumba namhlanje, ukusetyenziswa kobuchwephesha bokuqhubekela phambili ekuphuhliseni iimveliso zokubumba ezikumgangatho ophezulu yindlela efanelekileyo yokuba amashishini aphumelele kwimarike kunye nabathengi.

Ixesha lokuposa: Mar-10-2021